HICOVERY

Competitive, Sustainable, Profitable.

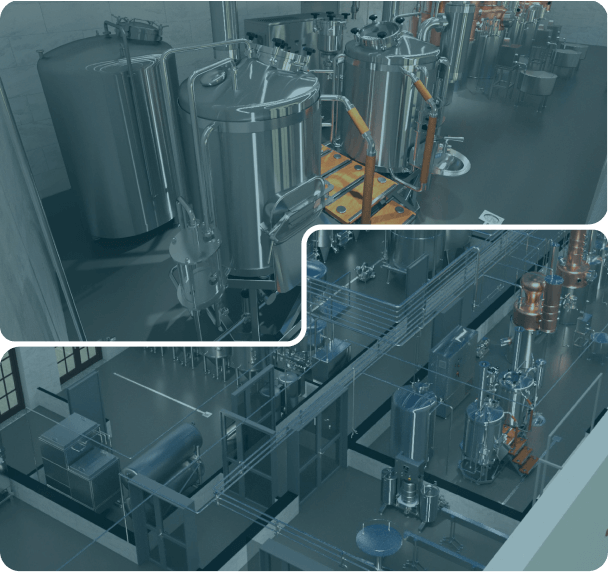

Advanced Waste Heat and Cooling Water Recovery Systems

Our technology recovers waste heat to deliver 110 ℃ super-pressurised water or equivalent low-pressure steam — cutting energy use by up to 75% and eliminating cooling water demand. See the details below.

Engineering the Impossible: How HICOVERY Works

Heat recovery is normally limited by standard technologies: only a small portion of waste heat can typically be reused, often just for preheating, because the heat input in many processes is far higher than what can be recovered.

Our high-efficiency HICOVERY technology changes that. It uses a practical multi-stage heat pump system to recover heat energy efficiently, producing either:

- 110℃ super-pressurised water

- Low-pressure steam at the same temperature

The heat pumps achieve a Coefficient of Performance (CoP) greater than 3, meaning 1 kW of electricity can recover around 4 kW of useful heat. With HICOVERY, up to 75% of the original process heat can be recovered, significantly reducing the energy demand of high-heat-intensive processes.

Turning Waste into Worth

Investing in HICOVERY is usually a high-value and complex decision, but where processes involve significant heat, it is well worth it – especially when considering the environmental benefits. If renewable electricity from solar or wind is available, costs can be further reduced, as large-capacity plants can run on a substantial amount of green energy.

Another major advantage of HICOVERY is that the cooling water is fully conserved through a closed-loop system. Only an initial filling is required, eliminating the need for ongoing water refills. This not only reduces environmental impact but also delivers considerable cost savings.

Tailored Integration for Each Plant

HICOVERY solutions are tailored to each plant’s specifications, effectively addressing compatibility challenges with existing technologies and integrating seamlessly into current production systems.

Please note that energy efficiency may vary depending on the specific setup of existing equipment. While HICOVERY can be integrated into existing layouts, its peak performance is optimised for greenfield projects.

Reducing Emissions

Minimisation of Cooling Water Usage

HICOVERY technology minimises (or eliminates) the need for cooling water, allowing companies to conserve vital resources and promote environmental responsibility.

Customised Compatibility

In-house developed, HICOVERY solutions are tailored to individual plant specifications, effectively addressing compatibility challenges with existing technologies and seamlessly integrating into current production systems.

Corporate Sustainability Commitment

Adopting HICOVERY demonstrates corporate responsibility for environmental preservation, supports long-term sustainable development, and enhances corporate credibility.

Reference: McKinsey & Company (2023) ‘Waste not: unlocking the potential of waste-heat recovery’. Available at: HERE

Contact Us

We’d be glad to hear from you. You’re welcome to share questions, concepts, or early-stage ideas.

Our first conversations are exploratory and technical in nature — with no commitment expected on your side.

Please contact the right person directly:

Opening Hours: M-F 9:00-17:00 CET