ROBOTIC Bottling & Packaging

Making industrial automation accessible for small-batch manufacturers.

Designed for Efficiency, Built for Endurance

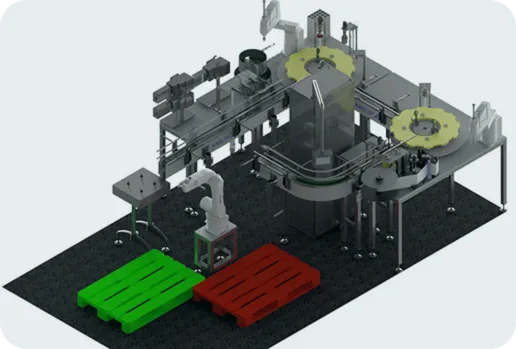

In collaboration with KARLWOOD, we bring industrial precision and lasting reliability to small-scale bottling and packaging.

Key Benefits

Our robotic systems are designed to deliver measurable gains across every aspect of production:

- Rapid ROI – Achieve quick returns alongside long-term performance.

- Enhanced Safety – Reduce manual errors and ensure consistent quality.

- Lower Scrap & Cycle Times – Streamline production for maximum output.

- Labour Optimisation – Operate with one or two operators instead of up to seven.

- Reduced Market Dependence – Minimise reliance on labour market fluctuations.

- Competitive Advantage – Gain reliability and independence from workforce uncertainty.

- Flexible & Adaptable – Easily reconfigure for different products or parameters.

Specifics

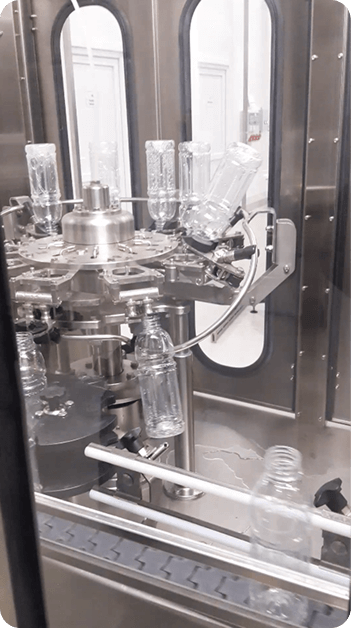

Highly efficient and ideal for bottling and packaging small batches (50–1,000 units/hour) such as:

cosmetics, creams, liquids, jams, chutneys, fruit juices, beverages, sauces, and spirits.

Perfect for filling, sealing, labelling, and marking.

Key features

- Requires minimal operating personnel – typically one operator

- Simple to set up and easy to operate

- Reliable, precise, and consistent

- Tailored to the specific requirements of each client

Dedicated to SMEs

“SMEs are not just businesses — they are families, communities, and the backbone of Europe’s middle class. I’ve seen first-hand how small-batch producers struggle with rising costs, labour shortages, and constant pressure from larger competitors.

Our ROBOTIC Bottling & Packaging solutions were designed with them in mind: to give SMEs the same advantages of efficiency, safety, and independence that big players enjoy.

For me, this isn’t just automation — it’s a way to help SMEs stay competitive, resilient, and future-proof.

This perspective shapes how we design systems: practical automation, fast ROI, and solutions that work in real-world SME environments.”

Lovassy Kamilla

Business Development, Lovassy & Co.

ROBOTIC Filling & Bottling

Automated solutions for small-batch manufacturers with high manual workload.

Explore our game-changing ROBOTIC filling, bottling, and packaging technology – developed in collaboration with KARLWOOD (the official service partner of industry-leading brand, Krones)

This custom-engineered technology

- provides short-term return on investment,

- guarantees greater production safety

- reduces scrap rate & cycle time,

- eliminates manual errors and delivers consistent quality performance in the long term,

- reduces dependency on manual labour from up to 7 operators to 1 or 2,

- reduces the plant’s dependence on the labour market,

- provides users with a competitive advantage over similar market players by ensuring reliability and independence from human resource uncertainty

- AND is easy to reset for different parameters/ for a different product niche.

Automation and robotics for safer, faster production.

Boost Output and Ensure Safety

What Makes Our Robotic Bottling Tech Revolutionary

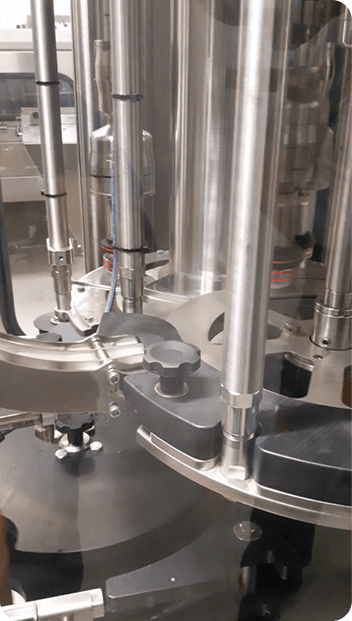

In small-capacity plants, where it would be extremely costly to install large, fully automated lines because they operate at a low capacity for which automated lines are not yet available, those plants tend to use semi-automated machines or manual labour.

With our technology, the robotic arm can be used to replace manual labour: one or two operators can do the work that would typically require four to six people, possibly even seven.

On the one hand, the investment is recouped relatively quickly in terms of specific labour, and on the other hand, this technology allows you to work with greater safety – it provides a high degree of production safety while also offering high precision.

On the other hand, which is also a significant advantage of our automatic bottling lines, is that these plants typically operate with low capacities because they usually produce small series of products. If someone has several small series products, switching over the automatic lines from one product to another takes a considerable amount of time and effort, and it can require half a shift or even a complete shift to set up the automatic lines.

They also have a high scrap rate due to the setup, as they maintain the same setup as if they were working in a large series. Still, they produce very few of these products here. So, it’s the same 10 rejects per 100 bottles as if they were making 50 bottles of the same batch.

Our bottling technology solves this problem, as it is highly flexible and can be easily reset. Thanks to its minimal setup requirements, it is very adaptable for use in small series. THIS makes our automated bottling technology TRULY REVOLUTIONARY.

Every System Is Custom-Built

Together with KARLWOOD our systems are u niquely designed for seamless compatibility with existing plant technologies, ensuring smooth installation and minimal disruption to operations. We provide comprehensive support at every stage—from initial design and planning through installation, commissioning, and ongoing assistance.

Contact Us

We’d be glad to hear from you. You’re welcome to share questions, concepts, or early-stage ideas.

Our first conversations are exploratory and technical in nature — with no commitment expected on your side.

Please contact the right person directly:

Opening Hours: M-F 9:00-17:00 CET